What is Inventory Management Case Study Assignment Help?

The process which involves the management of ordering, using, storing and selling the company’s product is known as inventory management unit. These all process includes management of warehouses, management of finished products and such like that processing of such items. In this unit all the processes accomplishes from management of raw materials to supply of finished products. The two most important and applied methods of inventory management is JIT and MR they are just-in-time and materials requirement planning. The inventory management case study assignment help students to understand each topic of related topic in better way. For companies who have complex supply chains and other management process takes help of inventory management.

How our Experts Help in Inventory Management Case Study Assignment Help?

The best way to show how our experts for inventory management case study assignment help is to check the work done by our expert written for similar type case:

Introduction:

The 21st century has brought new dimensions to the automotive business. With the advent of electric vehicles, advanced vehicle connections, and intelligent platforms, the challenges have quadrupled. Not only the OEMs but also the suppliers are now acclimatizing themselves to the new beginnings. The catastrophic event of COVID-19 in 2020 has disrupted the businesses across the globe and is a phase shifter for all. Organizations that will emerge the strongest post-COVID-19 will be the ones that can see the current emergency as an opportunity to overhaul their supply chains1. Automotive supply chains have to identify the challenges that are coming ahead and make themselves flexible in dealing with the disruption. The automotive supply chain requires advanced management techniques, vital information, and coordination. With globalization, supply chains have become more complex. Technology has helped to some extent for the perfect flow of information among the supply chain entities, but emerging trends make it difficult for companies to switch from one technology to another faster. Among all the leading automotive manufacturers and suppliers, Volkswagen has emerged as a strong player in the advancement of supply chains.

The production and inventory management at VW

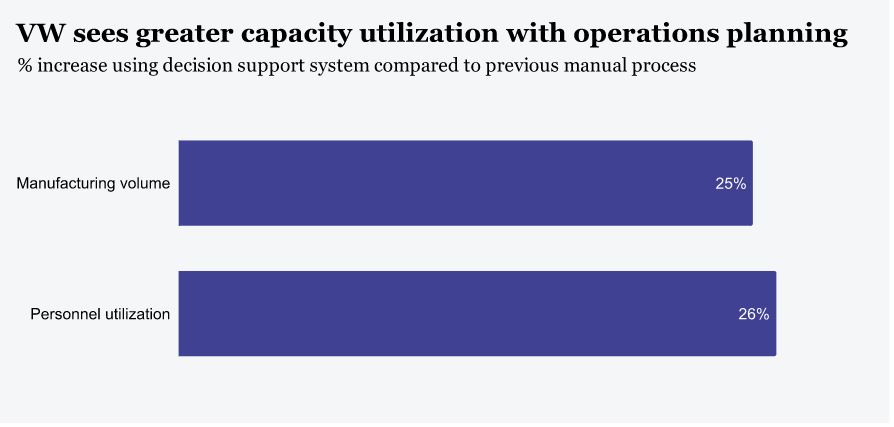

Volkswagen uses automated decision support (DSS tool to model spreadsheets from previous ERP data. This method is used for capacity planning at the Volkswagen Pre-Production Center (VPC). VPC often uses its staff to the whole utilization level and analyzes the manufacturing level (Wecken borg et al., 2020). This is part of the digitization of the supply chain. The following diagram is extracted from the research, and it says that VW experiences a higher jump in utilization after using the digital tools.

Fig 1: DSS utilization at VW

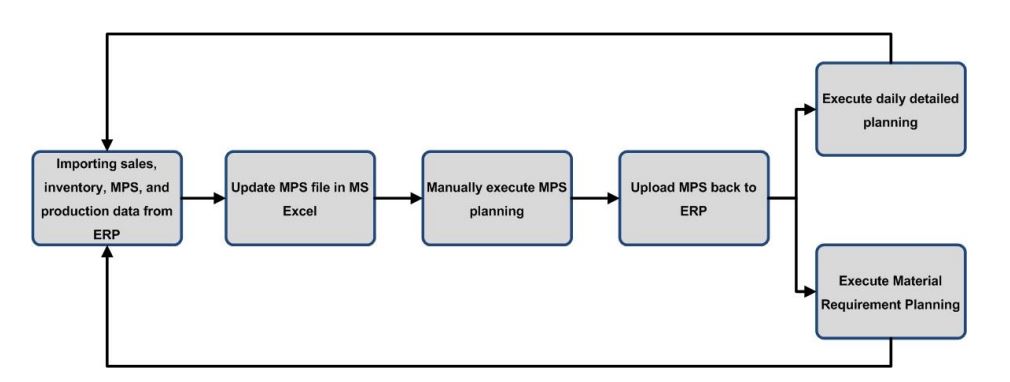

VW also uses a particular type of software called ILOG to produce customized cars for customers. Especially in European countries, the company uses this software to optimize the planning process2. This optimization software has reduced the schedule building process by 90%, which is very significant in a production process. If we take a look at the quantum of the production and the complexity of the production process, the Wolfsburg plant produces annually 800000 vehicles. This requires a lot of micro-level assembly planning and procurements. The company uses computerized ERP systems for material requirement planning. There are five inputs for an MRP, Master Production Schedule (MPS), Bill of Material (BOM), item master, orders, requirements of items that are needed, and MRP combines them. The company uses a demand-driven MRP model to produce the cars and the parts effectively. DDMRP is designed to connect the availability of materials and supplies directly from the actual condition using bills of materials (BOMs). A typical MRP flow in the automobile industry is shown below.

Fig 2: MRP stages at Volkswagen

The production planning process is performed on a weekly basis, where the master production schedule

(MPS) and detailed daily planning is made, as is shown in Figure 3. The MPS is a schedule with a 15-

week rolling planning horizon. The MPS’ detail-level is aggregated to whole weeks, which implies

that the weekly demand is merged into one value. The detailed planning has a four-week planning

horizon. Production is planned for each shift or hour specifically. Last-minute changes are made in this

planning whenever problems occur. The planning activity itself involves many manual steps. The demand and production data is retrieved from the enterprise resource planning (ERP) system, after which the MPS has to be manually updated and afterward uploaded to the ERP system. The planning is made manually, without the use of standardized methods or heuristics. The planner’s sole indicator to evaluate his planning performance is the inventory level, which colors white in the MS Excelfile (that is used to do the planning, see Appendix B) when the inventory level is within the desired bandwidth for that week. This is the safety stock (SS), which is derived from safety lead-time. Furthermore, customer orders are received by means of long-term forecasts, short-term orders, and sometimes-informal demand information is retrieved, for example, through informal contacts of account managers with customers. The recommendation that is given here for VW is to adopt a pull system and use lean manufacturing, which will reduce the inventory and increase customer satisfaction.

What comes under inventory management study assignment help?

There are many methods of inventory management but depending upon the type of business and how their products have been analysed they use inventory management. An appropriate inventory management strategy helps company to grow more and extend their branches in different areas. Inventory must be insured as if large inventory carries risk of spoilage, damage in demand. This can be very bad for company’s environment, small business takes care of stock manually but in big organizations they need a system of inventory management and best software for enterprise resource planning. All these can be studied under inventory management case study assignment help service. Case study provides in-depth knowledge of every topic.

Wanted to get best help in case study assignments. Kindly message us on WhatsApp +1-646-948-8918 or submit our form from menu.